The rubber wiring harness is used for protect the electronics from damage and keep the seals maintain the sealing through the object.In order to wear - resistant, waterproof, sealing and other functions.

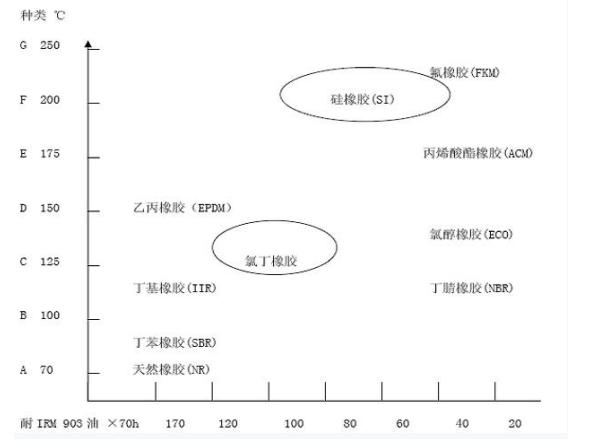

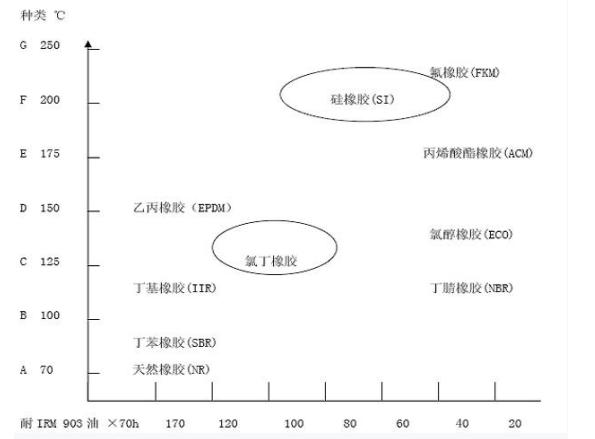

1.Test temperature of wiring rubber parts:

Material Test Temperature application

|

A1 |

80 degree |

car door rubber grommet |

|

A2 |

100 degree |

air conditioning, overhead light wiring harness rubber sheath |

|

A3 |

125 degrees |

forward cabin, engine nacelle rubber sheath |

2.Wiring harness property request

a. The wire harness rubber parts can be used at the temperature of 120 degrees for a long time, and the max temperature is 150 degrees, with good heat resistance.

b. Can work in rain and wet environment, anti- crack and anti- age on low temperature conditions and summer sun irradiation

c. Good elasticity, easy to recover, can be restored to the original state after repeated fatigue movement

d. Stable performance and precise size

|

Species |

NR |

EPDM |

CR |

NBR |

SBR |

|

Advantage |

Good mechanical properties and cold resistance.Alkali resistance, good vibration isolation |

Good acid and alkali resistance,Goodweather resistance and aging resistance, good electrical insulation and impact performance, low density, can be filled with high |

Excellent flame retardant, weather resistance, polar solvent resistance, good vibration isolation, good mechanical properties |

Good oil resistance,good seal and water-proof |

Its performance is similar to that of natural rubber. It has good aging resistance under the action of light, heat and oxygen |

|

Disadvantage |

not acid resistant, not oil resistant |

Slow vulcanization,poor self-adhesive and mutual adhesive energy, processing is difficult |

Hardened at low temperature, not easy to store, poor electrical insulation, high density, not easy to process |

Poor cold resistance, ozone resistance, not suitable for insulation materials |

Ozone resistance, tensile resistance, tear resistance, oil resistance as natural rubber |

|

Species |

NR |

EPDM |

CR |

NBR |

SBR |

|

Advantage |

Good mechanical properties and cold resistance.Alkali resistance, good vibration isolation |

Good acid and alkali resistance,Goodweather resistance and aging resistance, good electrical insulation and impact performance, low density, can be filled with high |

Excellent flame retardant, weather resistance, polar solvent resistance, good vibration isolation, good mechanical properties |

Good oil resistance,good seal and water-proof |

Its performance is similar to that of natural rubber. It has good aging resistance under the action of light, heat and oxygen |

|

Disadvantage |

not acid resistant, not oil resistant |

Slow vulcanization,poor self-adhesive and mutual adhesive energy, processing is difficult |

Hardened at low temperature, not easy to store, poor electrical insulation, high density, not easy to process |

Poor cold resistance, ozone resistance, not suitable for insulation materials |

Ozone resistance, tensile resistance, tear resistance, oil resistance as natural rubber |

To sum up, EPDM material can best meet the requirements of rubber wiring harness . It is widely used in automobile front cabin wiring harness, indoor floor wiring harness assembly, engine wiring harness assembly, front and back car door wiring grommet, and trunk wiring harness assembly

3.Attention in installation and use of wire harness rubber

The opening position of the rubber parts is divided into: the front cabin, four doors, the floor, the top and the back door. The front cabin opening should be selected on both sides as far as possible to ensure the continuity of the wiring harness and avoid the high temperature. The opening of the four doors should ensure that the height of the opening of the body is higher than the height of the door to move and prevent water from flowing into the room

Analysis of common problems of rubber parts, causes, solutions and measures:

|

NO |

Issue |

Analysis |

Measurement |

|

1 |

Rubber parts appear aging, cracking |

Material unqualified, wall thickness is too thin |

Ask manufacturers to adjust the material formula, the use of composite vulcanization system to increase the wall thickness of rubber parts |

|

2 |

Dynamicinfluence after rubber assembly |

No dynamic analysis was done or was insufficient |

Combined with the real car assembly situation to re-check, rectification, can manually make several dynamic rubber parts to adapt and rectification |

|

3 |

Hard to assemble |

hardness is too large, and the assembly space designed is too small |

Redefined hardness, formula expansion reduces the amount of carbon black filling, increased guide skeleton structure |

Contact us now!

Contact Person:Amy Guan

Email:sales2@fuste.com.cn

Phone/Wechat:86-18250877763

Skype/LinkIN:AmyGuan